Survey shows galvanized steel could enhance vehicle body life

A recent survey conducted by IIT Bombay has revealed that almost 60 percent of cars suffer from surface rust and corrosion effects like rust, blisters and perforation.

A recent survey conducted by IIT Bombay has revealed that almost 60 percent of cars suffer from surface rust and corrosion effects like rust, blisters and perforation. The survey, headed by Dr A.S. Khanna (Ph.D in Metallurgy from Madras University and professor at IIT Bombay), involved inspection of approximately 500 cars aging from 5-10 years. All the cars inspected were in the cost bracket of less than Rs 10 lakh.

The inspection involved the use of parking lot survey methodology, similar to that used in previous works conducted in North America in the 1990s. The said method allowed analysts to compare the North American surveys with their Indian counterparts. Considering the fact the Mumbai has an average humidity of 60 percent, rising up to 90 percent during monsoons, the coastal areas in and around the city were chosen for the survey.

The main motive of the study was to enlighten buyers about the importance of galvanizing their vehicles, which otherwise reduces the steel strength, fuel efficiency and emission problems in the long run.

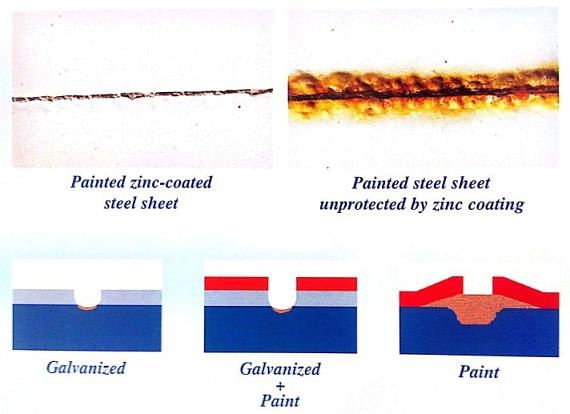

Galvanizing is basically a controlled coating of zinc on steel in order to protect it from corrosion. The zinc sacrifices itself slowly but steadily to protect the strength and safety of steel in the automobile body. Galvanized steel has been used for decades in Europe, North America, Japan and Korea for body panels and anti-perforation warranties are highly common in these parts of the world. However, in India, domestic cars are made from coated steels, which although give buyers the look and feel of international cars, they fail to provide anti-perforation warranties. Of late, Indian OEMs have started using galvanized and galvanneal steel for body panels, but only for export models. When you take two same cars of a particular OEM, the export model will have 70 percent of its body galvanized while the one for the domestic market will have only 20 percent of galvanized parts.

Commenting on the galvanization issue at a press meet in Mumbai today, Dr Khanna said, “Zinc is considered as a two-edged protector. It acts as a barrier to external factors as well as repairs the areas with cuts and blisters.”

What many people to fail to understand that applying coatings on a vehicle after being fully manufactured is not the same as using already-galvanized components during the manufacturing process. Explaining the scenario, Kenneth De Souza, corrosion specialist with International Zinc Association (Global), said: “Rather than coat the car body aftermarket, it is important to have a solid foundation with every part galvanized beforehand with electroplating galvanization.”

So why do car manufacturers refrain from galvanizing vehicles for the domestic market? Is it the cost factor or the availability of right materials? The answer is probably strange. A report by the International Zinc Association of India states that providing a galvanized/ Teflon/ UV protected underbody with a surface rust warranty up to 5 years only adds an estimated cost of Rs 9,000 to the whole value of the car (only 0.02% of the total amount). Moreover, companies like the Vedanta Group (producer of zinc-lead) claim that it is the absence of a standard regulation that prevents car manufacturers from using zinc-coatings for domestic markets.

“A Bureau of Indian Standards (BIS) specification for automotive coated steels is in the final draft stage, which shall hopefully change the game in the coming years,” said Kenneth De Souza. “A zinc-coating not only helps to increase the longevity of a vehicle but also improves the resale value significantly,” added Dr Khanna.

“Considering the fact the India is already the sixth largest car manufacturer in the world and it is set to grow from here along with added advantages like improved safety and fuel efficiency, weight reduction, reduced emissions, and increase in lifecycle cost, it is high time that domestic cars are galvanized the same way as international or export models,” summed up Kenneth De Souza.

RELATED ARTICLES

Maruti's Kharkhoda Plant construction in full swing

Maruti Suzuki has proposed to spend more than Rs 7,000 crore for the construction and commissioning of this plant which ...

July 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

July 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

Vemuri Young Artist from India Recognized as one of the Winners at 16th Global Toyota Dream Car Art Contest

Vemuri Young Artist from India Recognized as one of the Winners at 16th Global Toyota Dream Car Art Contest

By Takshak Dawda

By Takshak Dawda

14 Oct 2015

14 Oct 2015

20817 Views

20817 Views