Norma Group to supply thermal management line systems for 400,000 EVs

The systems will be installed in the electrically driven passenger cars of a major global OEM. Production of the line systems will begin in 2020, with some 400,000 EVs to be equipped with Norma Group systems by 2025.

The Norma Group, a global market leader in engineered joining technology, has bagged a huge order for supply of line systems for thermal management inside the battery packs of electric vehicles (EVs).

Norma develops line systems for thermal management of battery units for a leading battery manufacturer. The systems will be installed in the electrically driven passenger cars of a major international automobile manufacturer. Production of the line systems will begin in 2020, with some 400,000 electric vehicles to be equipped with Norma Group systems by 2025.

“As an industrial equipment supplier with a strong focus on the automotive sector, our ambition is to play an active role in shaping the growth in the area of electromobility,” said Dr. Michael Schneider, member of Norma Group’s Management Board. “This order once again illustrates that leading automobile manufacturers are relying on Norma Group’s development expertise for demanding electromobility projects.”

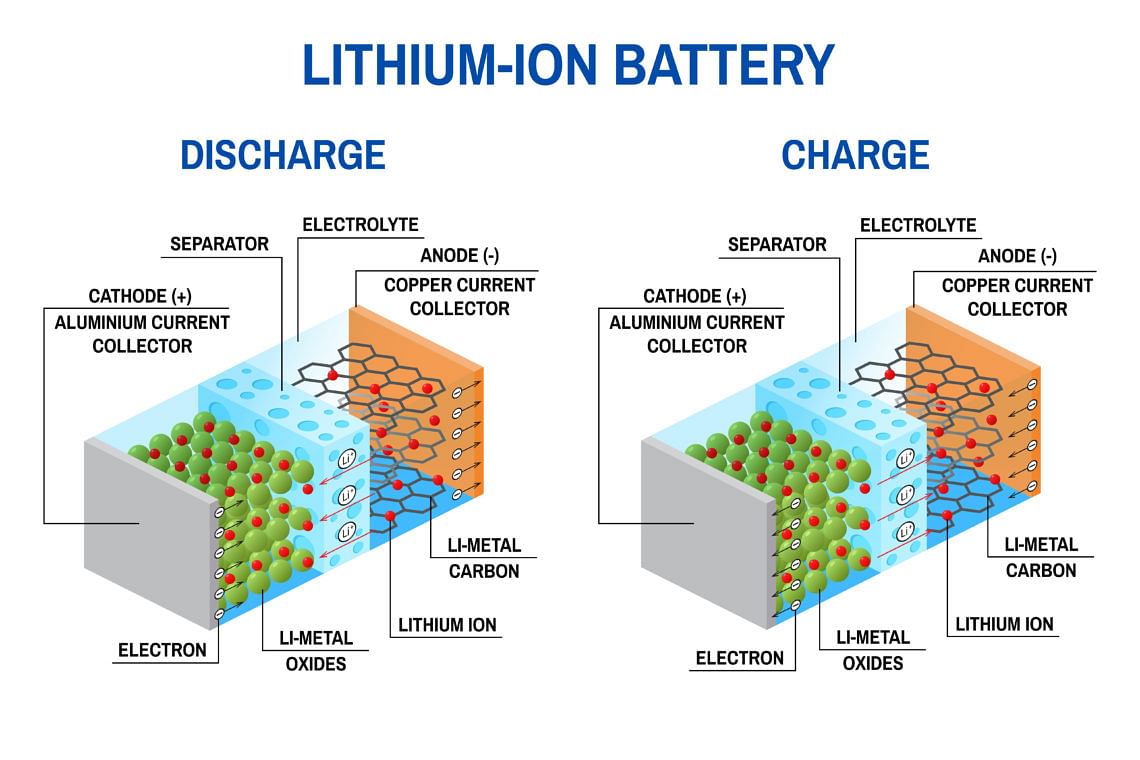

The thermal management line systems are used inside the battery packs of EVs and guarantee the correct operating temperature of the battery cells. In this way, the systems make a significant contribution to the optimal performance of the battery and help increase the range of the vehicles. The service life of the battery is also substantially influenced by the thermal management of the cells. Integrated temperature sensors in the line systems enable particularly precise control and regulation of the coolant temperature.

Battery-internal thermal management line systems must meet high design and technical requirements and battery packs must accommodate as many battery cells as possible in order to achieve the highest possible battery performance. Norma says due to their optimal compactness and efficient line routing, its management systems can be installed inside the battery in a very space-saving format.

To ensure that the batteries function reliably and safely in the long term, it is also essential that the line systems and all connections be absolutely leak-free. In development partnership with the customer, the thermal management line systems were optimized to minimum tolerances. The use of laser welding technology meets the customer’s high requirements for precision, cleanliness and tightness of the connections. This high-precision manufacturing method allows for thermoplastic joining elements to be reliably and safely joined to thermoplastic smooth or corrugated pipes.

The line systems for thermal management are produced at the Norma Group plant in Pilica, Poland. An on-site test laboratory supports rapid product development and continuous quality control.

RELATED ARTICLES

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

US car majors hit the brakes on driverless cars

Ford Motor and Volkswagen to close self-driving startup Argo AI, due to lack of technology and clear regulations.

Autoliv and Geely to develop advanced safety tech for future vehicles

Scope of cooperation includes safety for high-level autonomous driving, intelligent steering wheel technology, a 360deg ...

By Autocar Pro News Desk

By Autocar Pro News Desk

24 Sep 2019

24 Sep 2019

9137 Views

9137 Views