Nissan to use ultra-strong, high-formability 980 megapascal steel to reduce vehicle weight

World-first innovation from Nissan, Nippon Steel and Sumitomo Metal Corporation claimed to help lower emissions and improve performance by reducing vehicle weight.

Nissan is to build more models using a new type of steel that combines high-tensile strength with a previously unachievable degree of formability, resulting in lighter vehicles that can help lower emissions while protecting occupants.

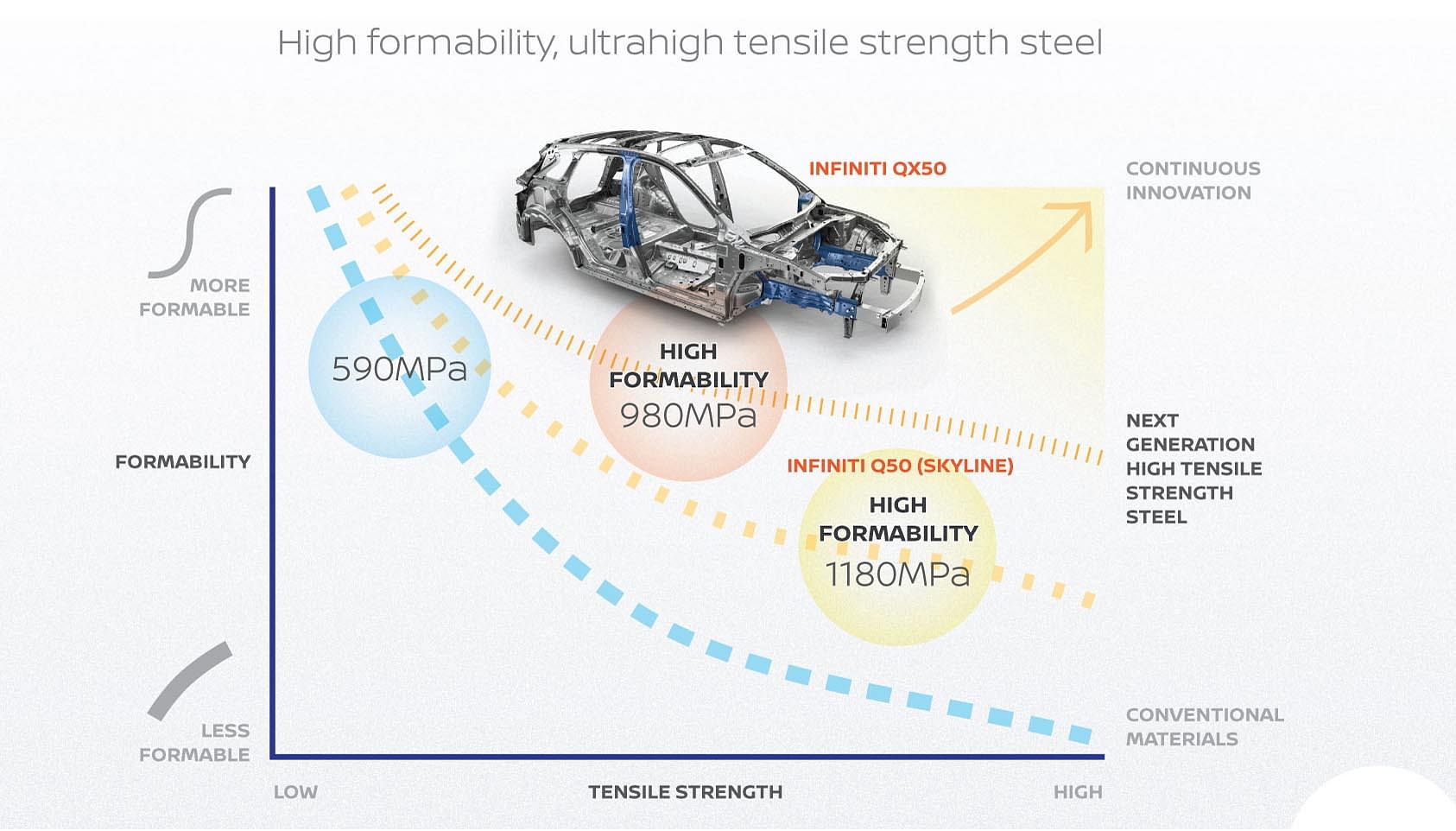

Nissan is the world’s first carmaker to use the high-formability steel, with a tensile strength of 980 megapascals, which was jointly developed by Nissan and Nippon Steel and Sumitomo Metal Corp. The steel’s combination of stamping formability and strength makes it possible to form parts with complex shapes that are thinner and lighter than those made of conventional high tensile strength steel, while maintaining the ability to absorb energy in a collision.

Infiniti QX50 is the world’s first vehicle with front and rear side members made from 980-megapascal ultra-high tensile strength steel, along with other body frame parts.

The Infiniti QX50 premium midsize SUV, which went on sale in the US in March, is the world’s first vehicle with front and rear side members made from 980-megapascal ultra-high tensile strength steel, along with other body frame parts. Nissan plans to expand the use of the material, which enhances fuel efficiency as well as driving performance by lowering vehicle weight, to other models.

Nissan launched a sustainability plan this month that calls for lowering CO2 emissions from its new vehicles by 40 percent by fiscal year 2022, compared with fiscal year 2000. The company is aggressively developing technologies to expand the use of ultrahigh tensile strength steel, aiming for it to make up 25 percent of the company’s vehicle parts by weight. The material makes up 27 percent of the new QX50.

The 980-megapascal steel developed with Nippon Steel and Sumitomo Metal can be cold-pressed, making it suitable for mass production. This will help contain increases in vehicle cost.

RELATED ARTICLES

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

US car majors hit the brakes on driverless cars

Ford Motor and Volkswagen to close self-driving startup Argo AI, due to lack of technology and clear regulations.

Autoliv and Geely to develop advanced safety tech for future vehicles

Scope of cooperation includes safety for high-level autonomous driving, intelligent steering wheel technology, a 360deg ...

By Autocar Pro News Desk

By Autocar Pro News Desk

19 Jun 2018

19 Jun 2018

5583 Views

5583 Views