BASF's new German facility to supply cathode active materials for EV battery

The new state-of-the art plant will produce cathode active materials (CAM) with an initial capacity enabling the supply of around 400,000 EVs per year.

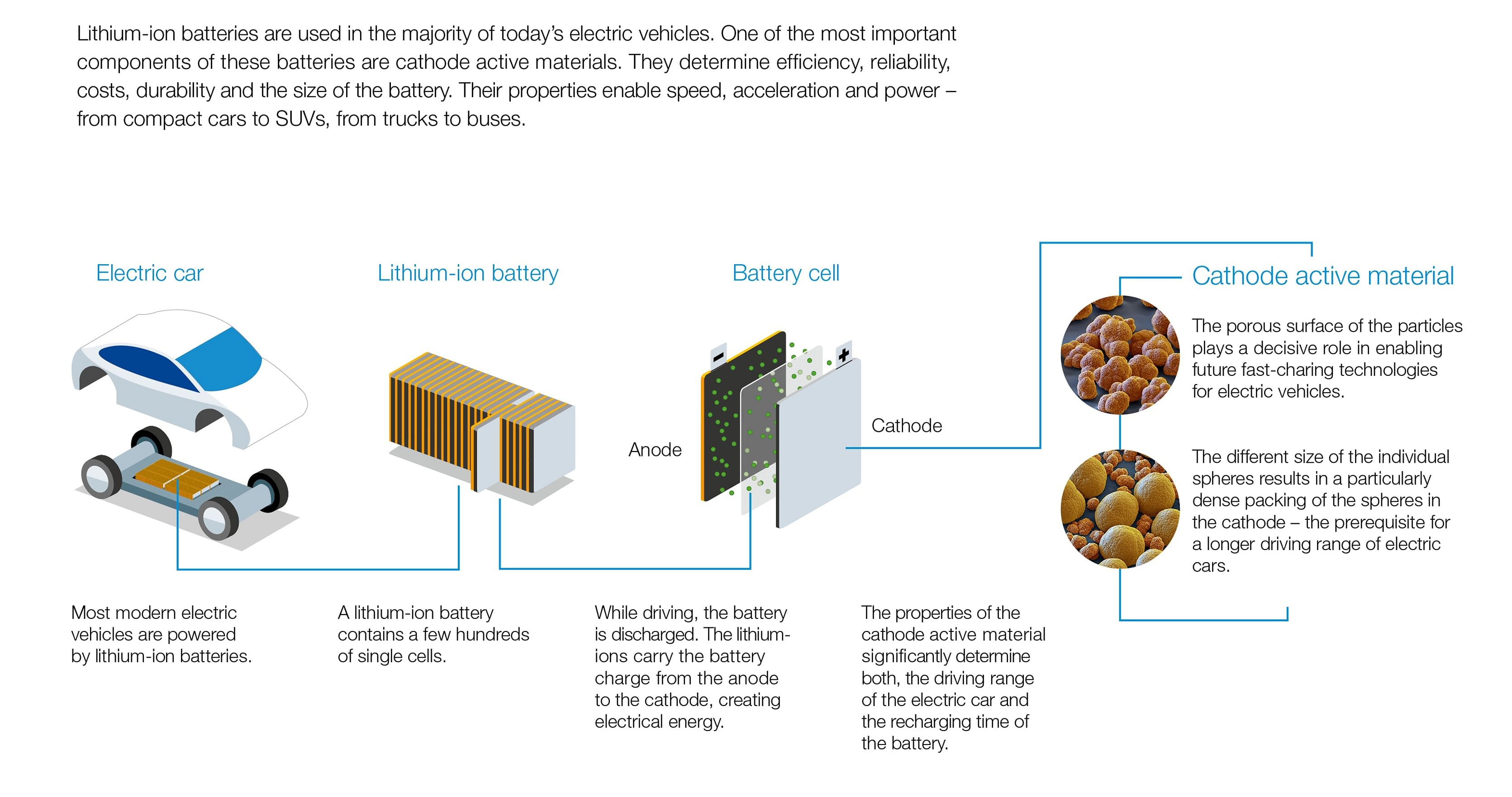

BASF has announced a new battery materials production site in Schwarzheide, Germany, as part of its multi-step investment plan to support the European electric vehicle value chain. The new state-of-the art plant will produce cathode active materials (CAM) with an initial capacity enabling the supply of around 400,000 full electric vehicles per year with BASF battery materials.

The company says the innovative cathode materials by BASF increase the performance of batteries, promoting the success of climate-friendly mobility.

The Schwarzheide plant’s modular design and infrastructure allows for the rapid scale-up of manufacturing capacities enabling BASF to meet increasing customer demand for the European EV market. The Schwarzheide plant will use precursors (PCAM) from BASF’s previously announced plant in Harjavalta, Finland, with the production scheduled to begin in 2022.

Dr Peter Schuhmacher, president, Catalysts division at BASF said: “The plants in Finland and Germany will offer our customers reliable access to tailored high-nickel cathode active materials in proximity to their European manufacturing facilities."

With these investments in Finland and Germany, BASF says it will become the first CAM supplier with local production capacities in three major markets – Asia, the United States and Europe. The chemical and material major will become the leading supplier with a reliable, sustainable and European-based supply chain which will comprise base metal supply, particularly nickel and cobalt, precursor production, and cathode material production within one region.

The Schwarzheide facility uses an energy-efficient gas and steam turbine power plant that operates on the principle of combined heat and power generation. It is currently being modernised to further increase its eco-efficiency. Until the battery materials plant is commissioned, the integration of renewable energies is also planned. The Harjavalta plant will utilise renewable energy resources, including hydro, wind and biomass-based power. This advantageous energy mix will provide CAM material with a very low CO2 footprint.

The investments in Harjavalta, Finland, and Schwarzheide, Germany, reinforce BASF’s support of the European Commission’s agenda towards a European battery production value chain and are part of the 'Important Project of Common European Interest (IPCEI)' that was approved by the European Commission on December 9, 2019 under the European Union state aid rules.

RELATED ARTICLES

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

Sept 2024 From R&D incentives to EV infrastructure: What auto components industry expects from Budget 2024

US car majors hit the brakes on driverless cars

Ford Motor and Volkswagen to close self-driving startup Argo AI, due to lack of technology and clear regulations.

Autoliv and Geely to develop advanced safety tech for future vehicles

Scope of cooperation includes safety for high-level autonomous driving, intelligent steering wheel technology, a 360deg ...

By Autocar Pro News Desk

By Autocar Pro News Desk

12 Feb 2020

12 Feb 2020

10078 Views

10078 Views